Enamel is a glass crystal used in decoration. It also makes enamel jewelry. Enameling is a technique commonly used in costume jewelry, it is also found in fine jewelry. It consists of heating shards of glass at very high temperatures to obtain colorful decorations.

The enamel is part of the family of glasses, so it has the same characteristics as the latter: resistance and unalterability.

When the enamel is applied to terracotta, we obtain ceramics. The use of terracotta makes it possible to handle a light and easy-to-shape material, then the enamel brings the hardness, resistance, and color.

The Enameling Process

The enameling process has four distinct steps:

- The first is the manufacture of the crucible. The latter can be done by hand in refractory clay. It must be dried for seven months at a temperature of 30 ° C at the beginning and then gradually increased to 1400 ° C. This process should last eight days. The crucible is a container for cooking the enamel.

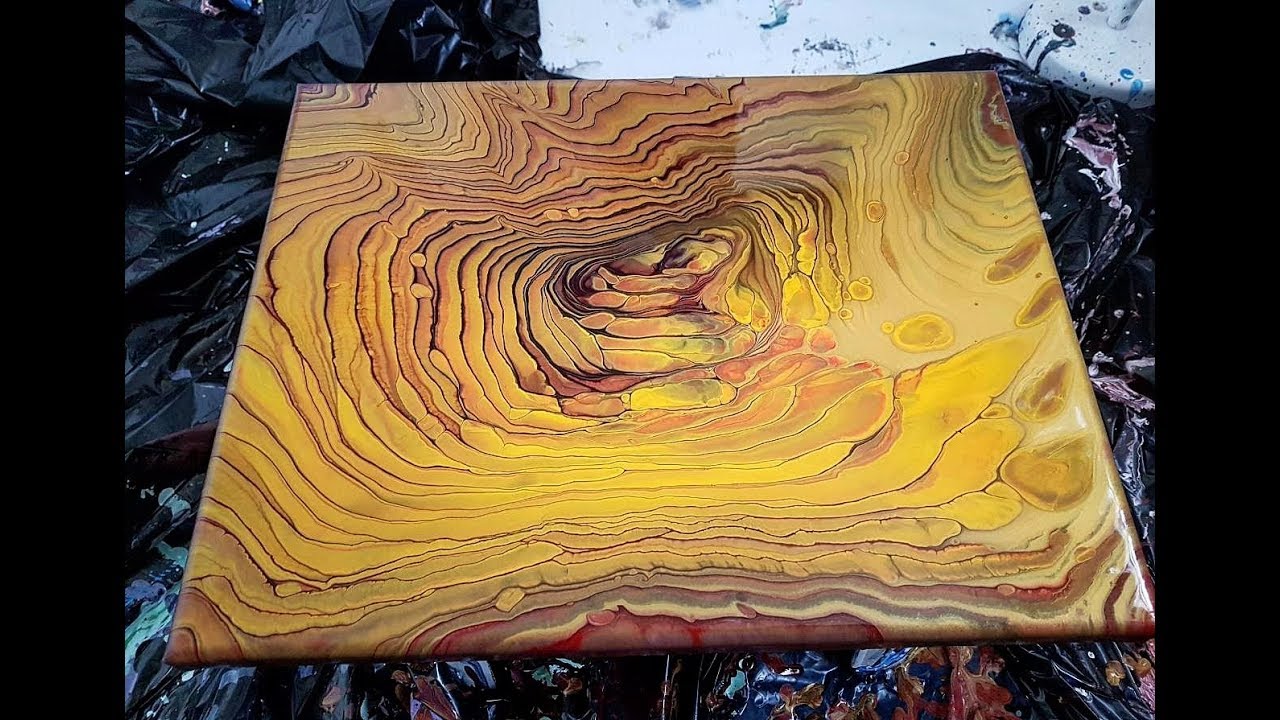

- The second step of enameling is fusion. This consists of melting all the components to produce enamel.

- The third stage of manufacture is the exit of the enamel infusion. After 14 hours of time, at a temperature of 1400 ° C, the enamel melts in the crucible. Then, it is cooled in a mold.

- The fourth and final step in the process is grinding. This stage consists of transforming the enamel powder. Making enamels requires these steps to be followed.

Different Enameling Techniques:

This technique involves creating patterns using a flat, thin wire, bent and curved. This wire is deposited on its edge, then heated on the metal to create compartments that will then be filled with fine powder enamel.

The piece is then baked so that the enamel merges with the metal base.

1. The Champlevé

With the champlevé technique, the metal is dug and leveled by etching or hammering to create cells. These cells are then filled with enamel powder to obtain beautiful patterns once the enamel melted after cooking.

2. Inlaid Enamel Also Called Enamel In Round Bump

The enamel is applied on a shaped surface, even on carved figurines. It is applied wet but is held in place by a thin layer of organic glue.

3. Enameling With Low Reliefs

Inspired by the champlevé technique, this consists of engraving the pattern on the surface of the metal which is then covered with translucent enamel. This creates a gradient of color shades: the deeper areas become darker.

4. Painted Enamel

For this technique, the enamel is very finely ground and mixed with a fine paste with pure oil.

5. The Enamel Plique Up To Date

Here the enamel is not fused to the background, it adheres to the sides of the metal. The pattern is cut in a sheet of metal, and the enamel, wet, adheres to the cells by capillarity. This technique creates a stained glass effect by letting the light through the translucent enamel.

Enameling is a delicate technique that requires very good knowledge.

There are resins to obtain a result visually similar to enamel but without cooking. These resins can be used on almost all substrates and, once mixed with a hardener, freeze without going through the delicate stage of cooking.

However, the resins have not at all the same properties as enamel and are much less resistant than the latter.

Enamel Jewelry

The enamel makes jewelry. The enamel jewels require the fusion of the enamel powder.

For this, it is necessary to use an adequate material of high temperature (about 150 to 180 ° C). After, the jewel must be cooled.

It can melt several times when needed. Enamel jewelry is a personalized accessory.